0102030405

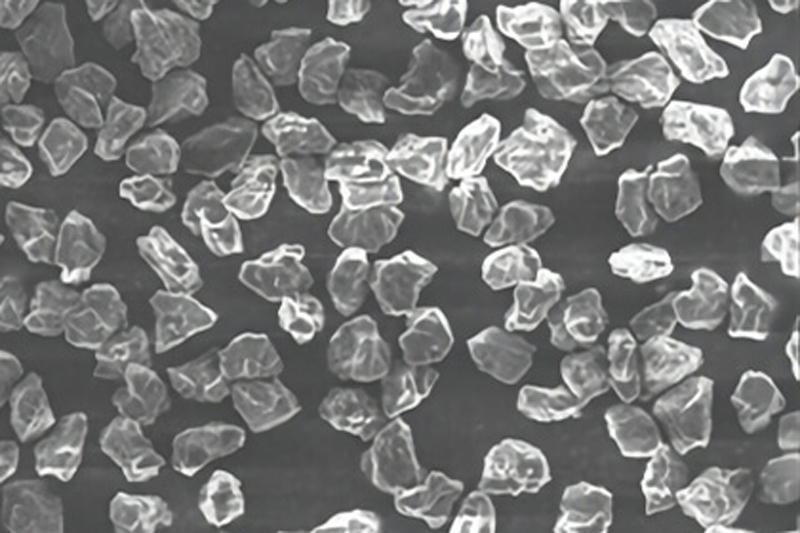

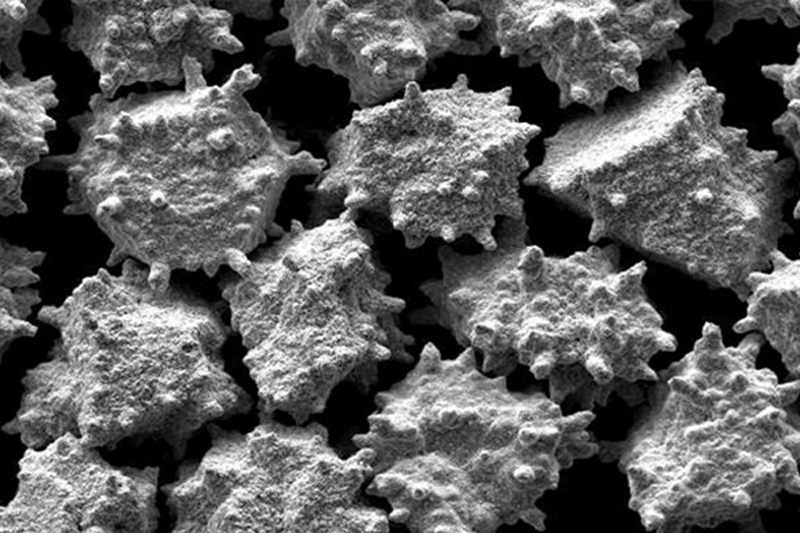

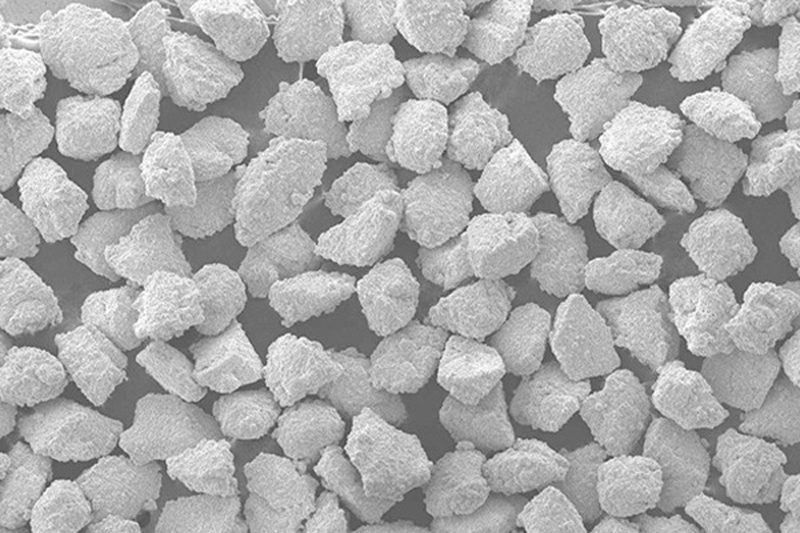

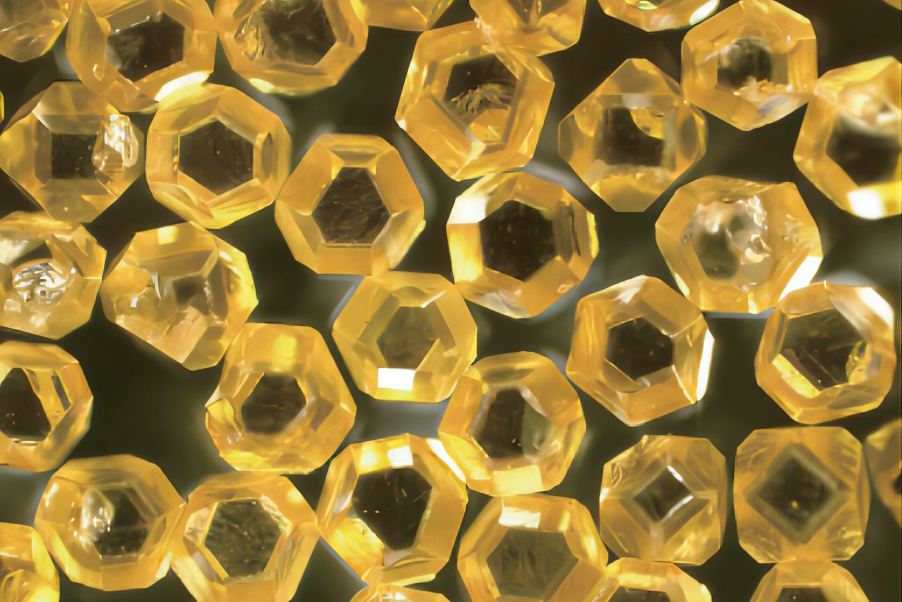

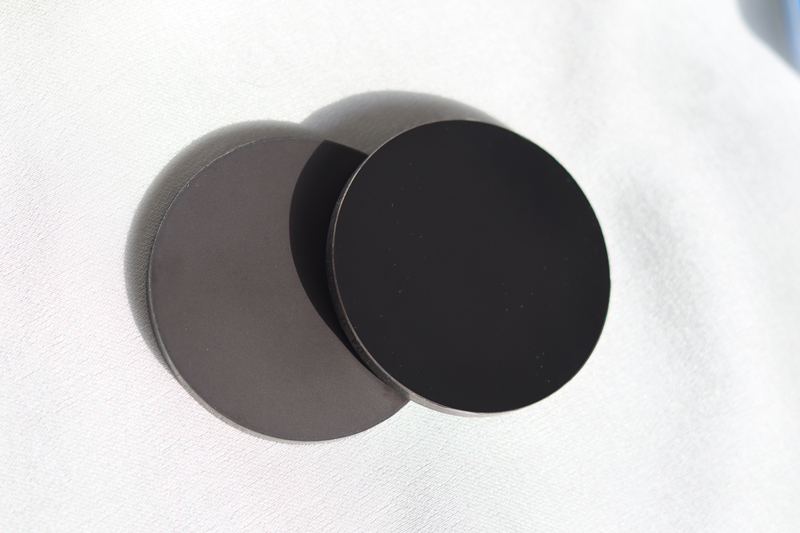

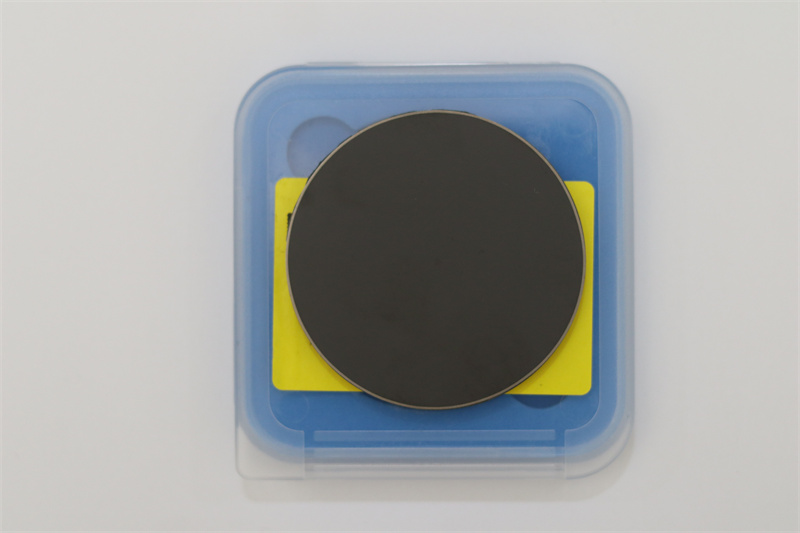

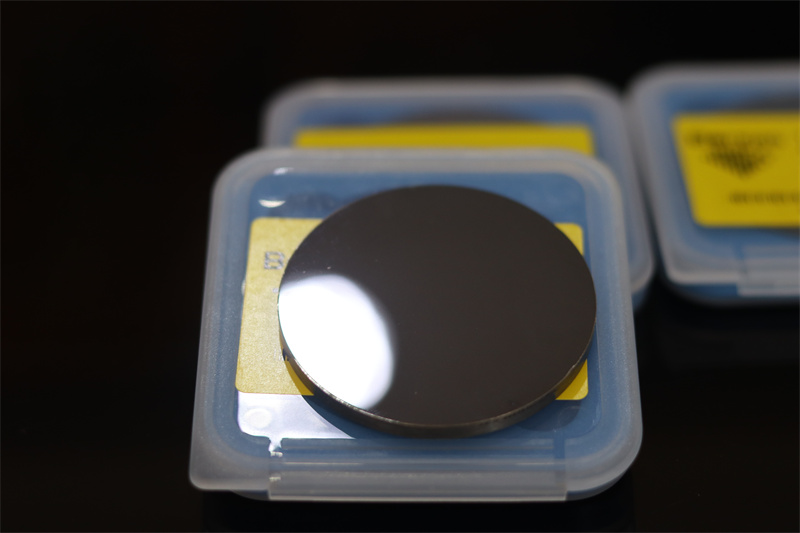

PCBN(Polycrystalline Cubic Boron Nitride)

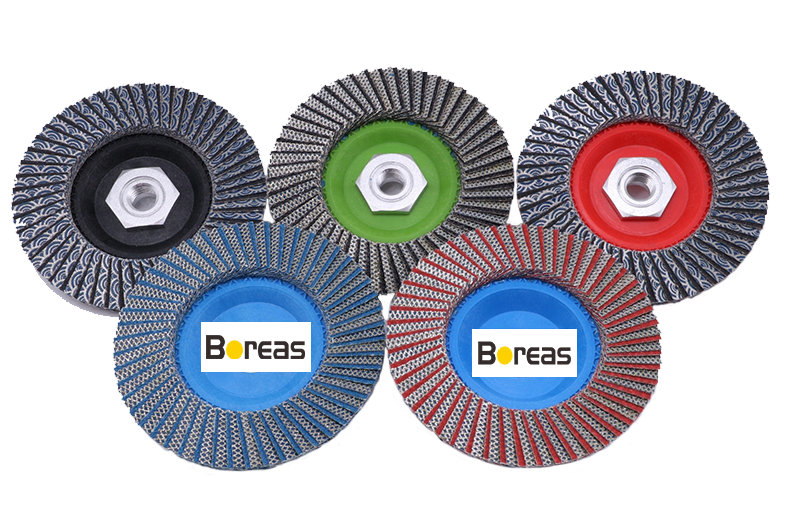

Application areas of PCBN tools

High-speed and ultra-high-speed cutting and machining technology

PCBN tools are most suitable for high-speed cutting of cast iron, hardened steel and other materials. By the PCBN tool cutting cast iron and hardened steel when the tool back face wear and cutting distance relationship can be seen: when the cutting speed over a certain limit, the higher the cutting speed, PCBN tool back face wear rate instead of smaller, that is, high-speed cutting under the life of the tool instead of high, this feature is especially suitable for modern high-speed cutting processing.

2. The best tool material for hard cutting technology

Hardened hardware (hardness HRC55 or more) finishing, usually using grinding processing methods to complete, however, with the development of cutting tool materials and lathe (especially CNC lathe) machining accuracy, hard cutting instead of grinding to complete the final machining of the parts has become a new way of finishing, this car instead of grinding process has the following advantages:

(1) can improve machining flexibility, breaking through the limitations of grinding wheel, by changing the cutting edge and the way to go can be machined out of the geometry of the workpiece;

(2) cutting processing in the increasingly serious environmental issues, grinding processing waste liquid and waste is increasingly difficult to deal with and remove, and harmful to the human body, and hard cutting without adding coolant, which is of great significance;

(3) High cutting efficiency, short processing time, small equipment investment costs, can reduce processing costs;

(4) removal of the same volume of energy consumed only 20% of the grinding, so less cutting heat generated, the machined surface is not easy to cause burns and small cracks, easy to maintain the integrity of the surface properties of the workpiece;

(5) Under the same metal removal rate, hard cutting saves energy compared with grinding.