0102030405

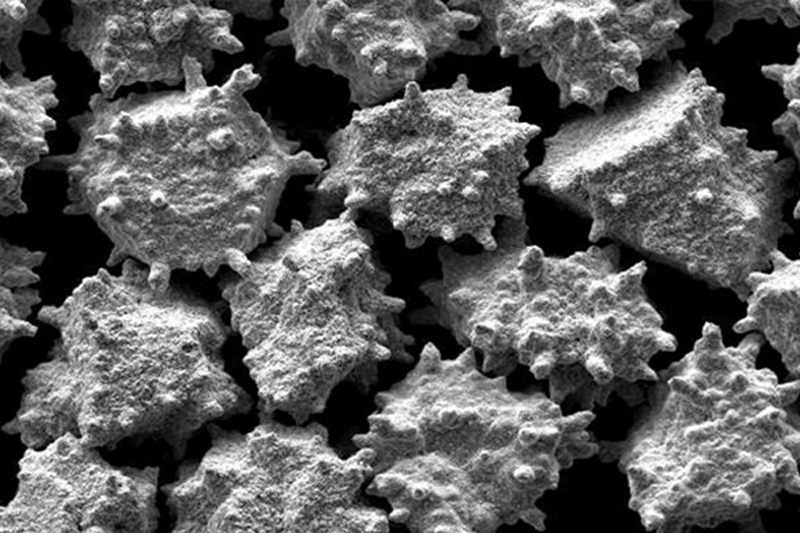

[BRM-A] / Blocky Series Micron Diamond Powder

Classifications

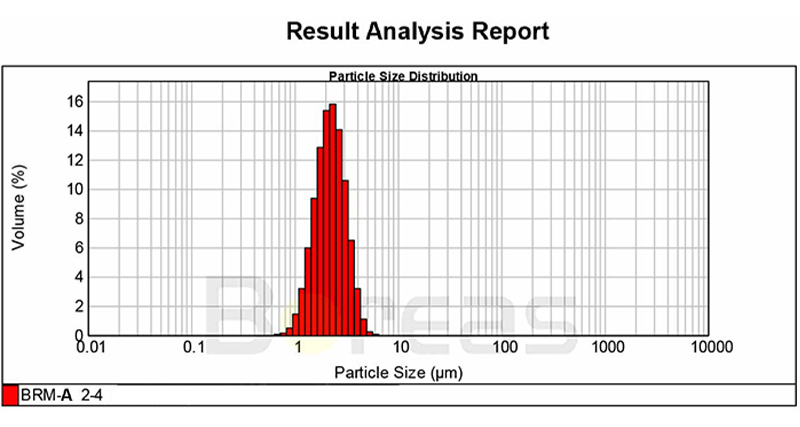

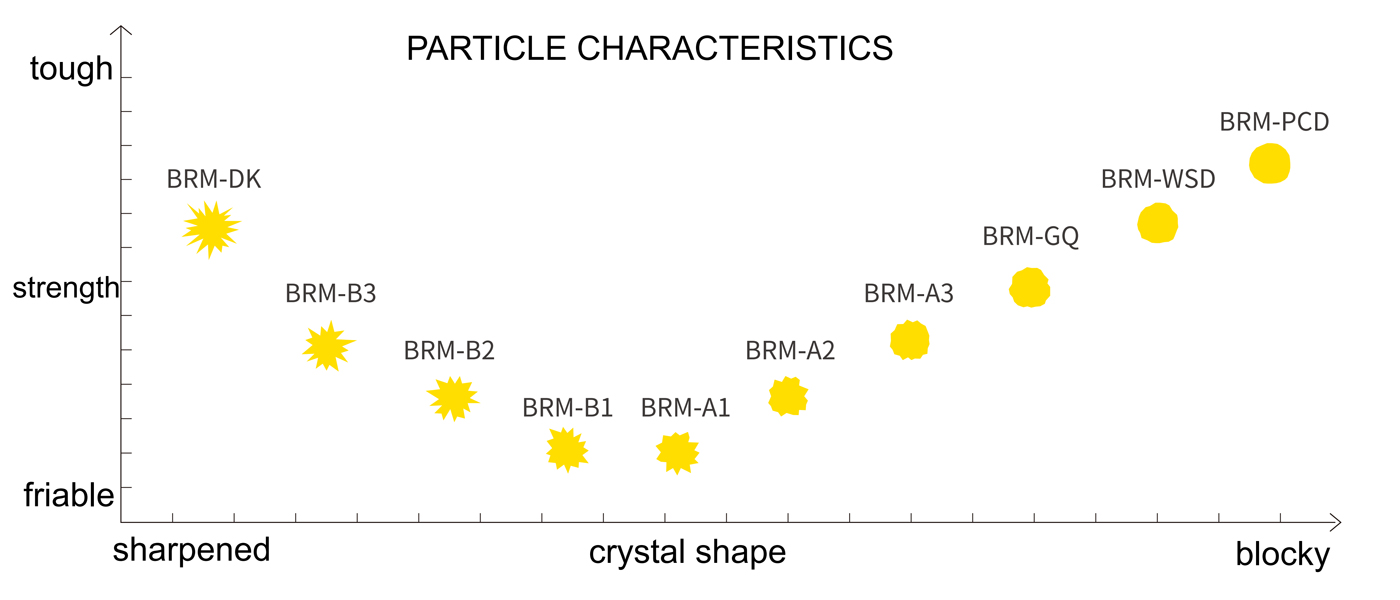

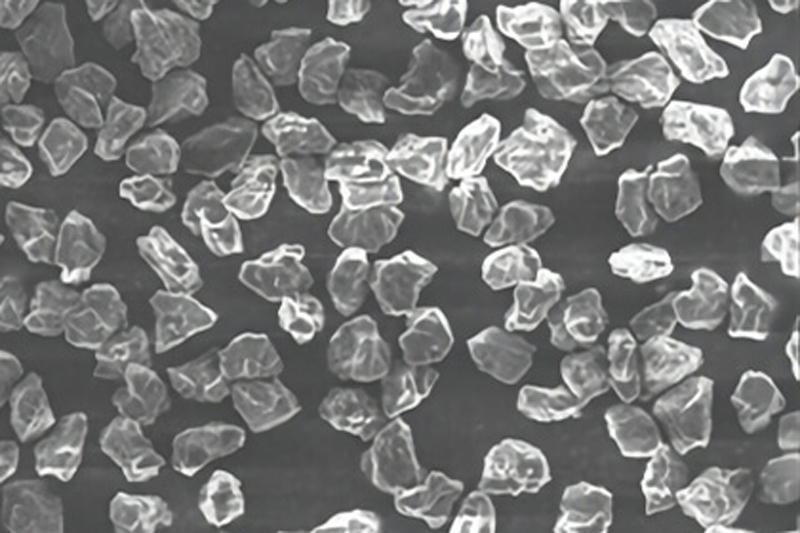

High strength and grinding force, uniform and near-spherical particle shape, concentrated particle size distribution (PSD), low impurity, good dispersion, and wear resistance are key characteristics of this powder. Its complete crystal and block shape, along with concentrated particle size distribution, enable high cutting ability while effectively preventing deep scratches. Additionally, boasting high purity with an impurity content of less than 0.5%, the powder ensures a clean surface for the grinding workpiece, avoiding the presence of abnormal substances. The use of specific grinding processes guarantees a consistent, blocky particle shape, crucial for achieving high stock removal rates and uniform surface quality.

BRM-A series diamond micro powder products are gray or off-white, categorized into three types, A1, A2, and A3, based on their strength from high to low.

BRM-A1 is the economic grade, low-grade and hardness, offering high cost performance.

BRM-A2 diamonds are moderate grade and hardness, suitable for various general free abrasives or solidified abrasives

BRM-A3 diamonds are high-grade, very low impurity content, ideal for high-intensity grinding;

Applications

Used for Metal bond, Vitrified bond, Electroplated diamond tools, diamond paste and slurry for cutting & grinding & polishing electronic components, optical glass, precision ceramics, tungsten carbide, PCD/PCBN, gems, etc.

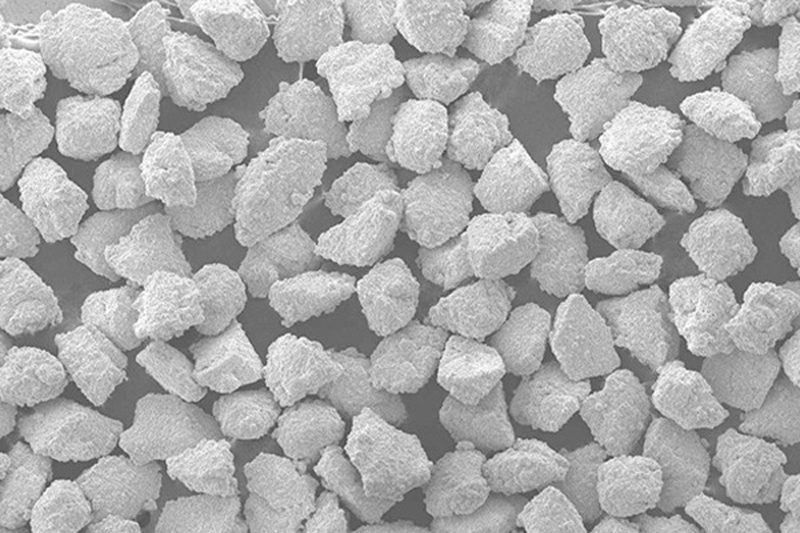

BRM-GM Series

The BRM-GM series diamond typically exhibits a green color, irregular shape with lower toughness. transitioning from dark green to gray as the particle size decreases, owing to its unique production and processing method. This product offers good self-sharpening properties, and is suitable for a wide range of applications in resin-bonded diamond tools.

Suitable for resin bond, ceramic bond, eletroplating diamond abrasive tools, such as the diamond grinding wheel, diamond abrasive fickerts. Widely used for processing stones, concretes, ceramics, etc.

Micron Diamond Available Grit Size Chart

Size |

0-0.25 |

0-0.5 |

0-1 |

1-2 |

2-4 |

3-6 |

4-8 |

5-10 |

6-12 |

7-14 |

8-12 |

BRM-A |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

Size |

8-16 |

10-20 |

12-22 |

15-25 |

20-30 |

22-36 |

20-40 |

30-40 |

35-45 |

36-54 |

40-60 |

BRM-A |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

![[BRM-A] / Blocky Series Micron Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/6602456b4ec7326141.jpg)