0102030405

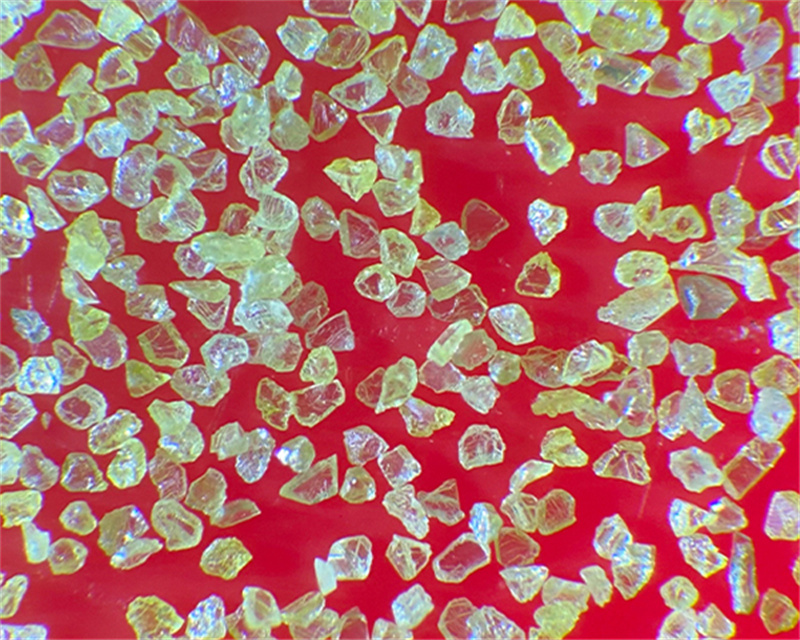

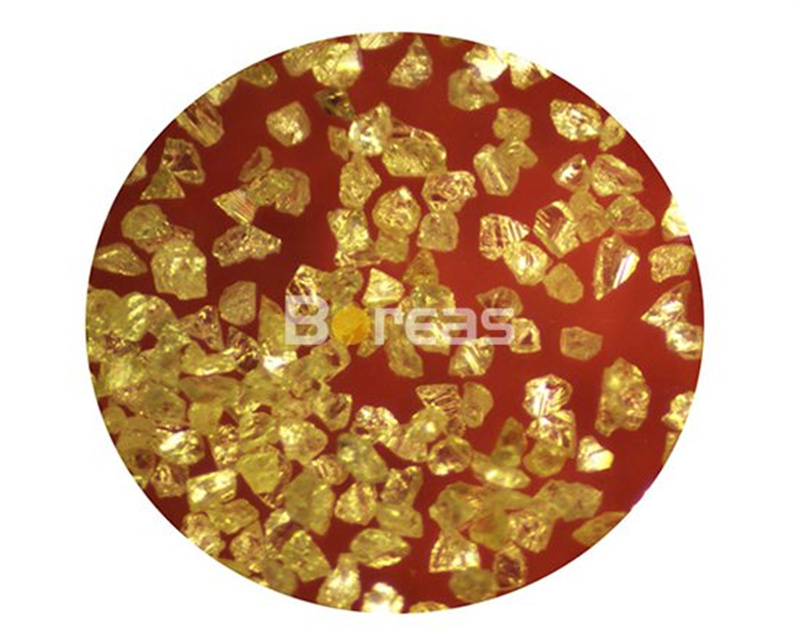

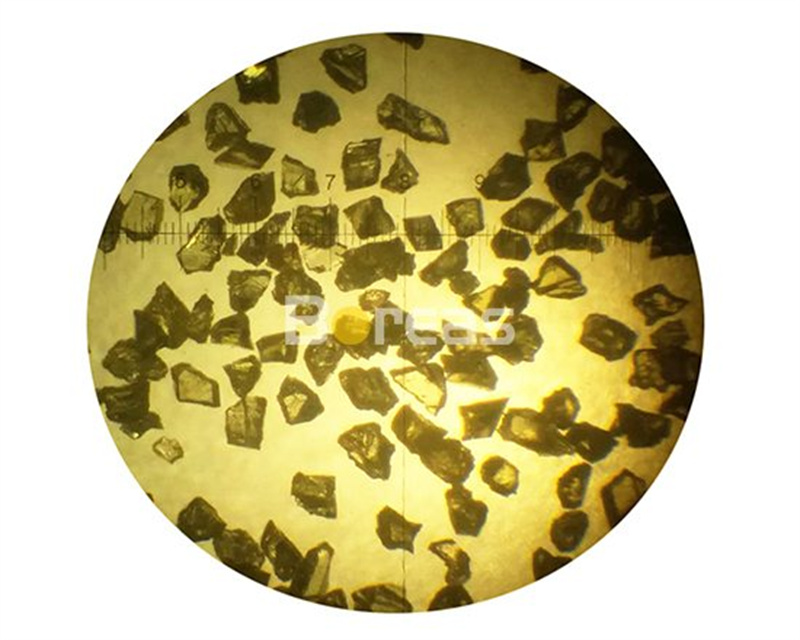

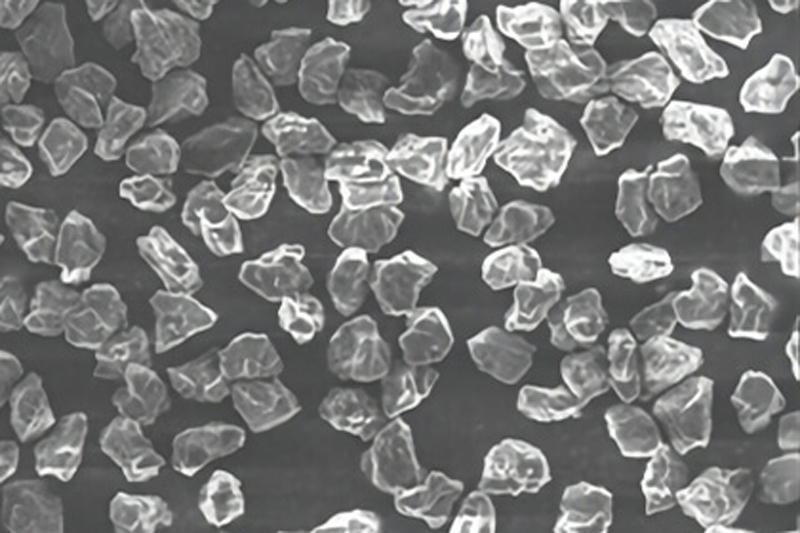

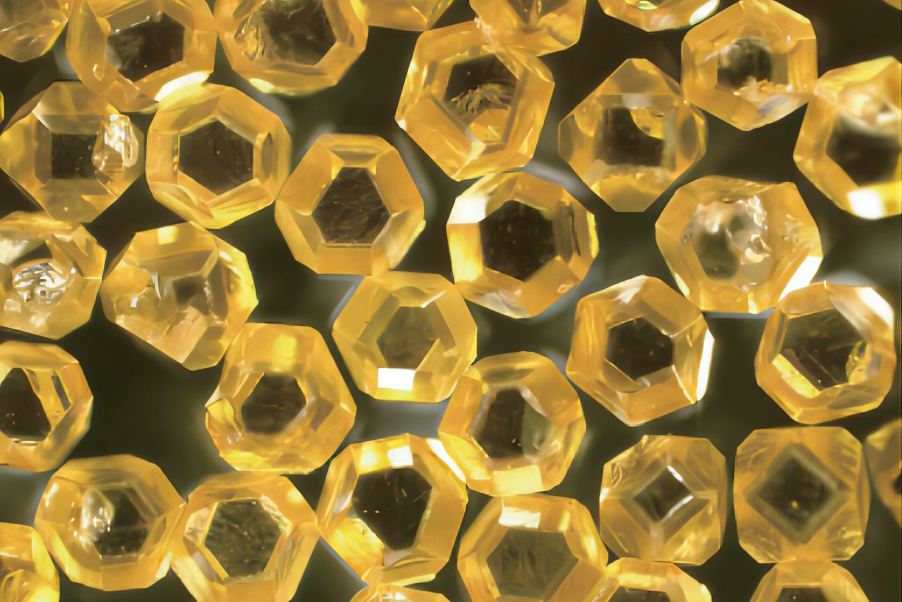

[BRM-P] Crushed Mesh Diamond Powder

BRM-P1

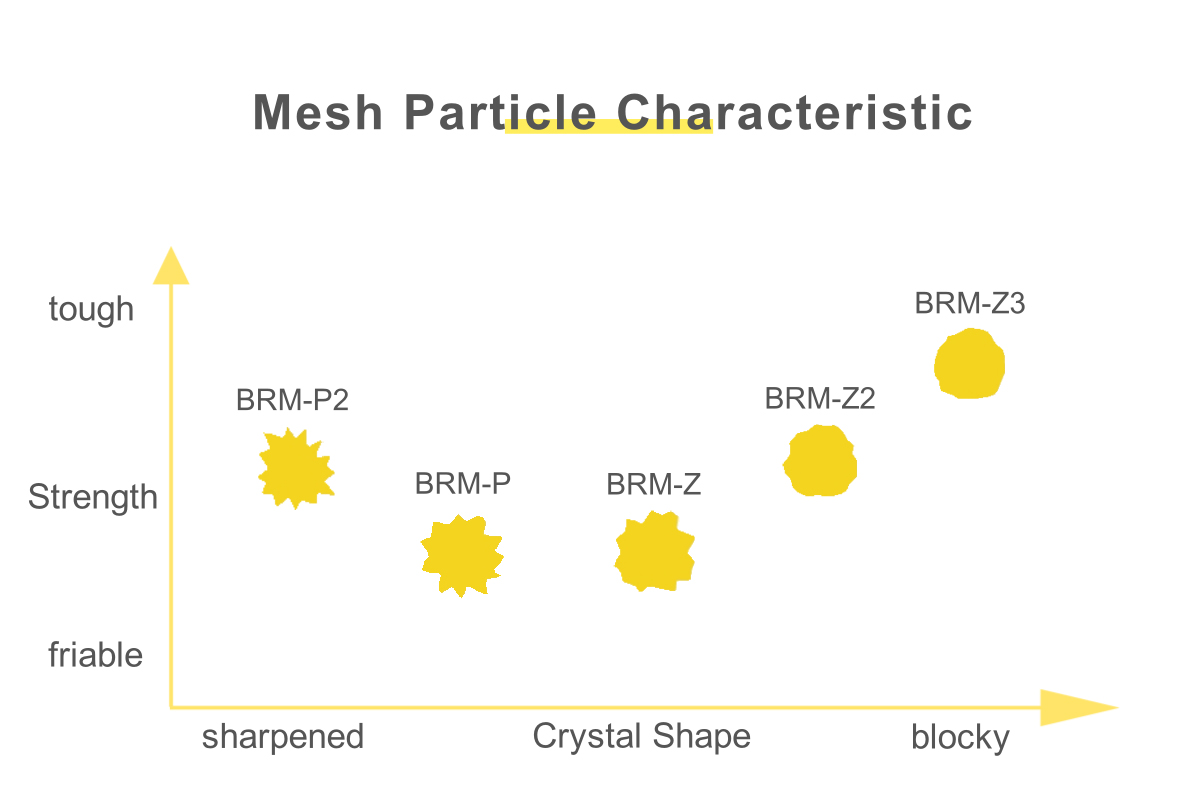

Medium toughness, angular shape, produced by using economic MBD diamond as raw materials. Irregular shape of the diamond particles ensures that new cutting edges are continually generated during the grinding process. Additionally, the textured surface of the particles enhances their ability to bond effectively with resin and vitrified systems. Diamond Nickel and Titanium coated is available.

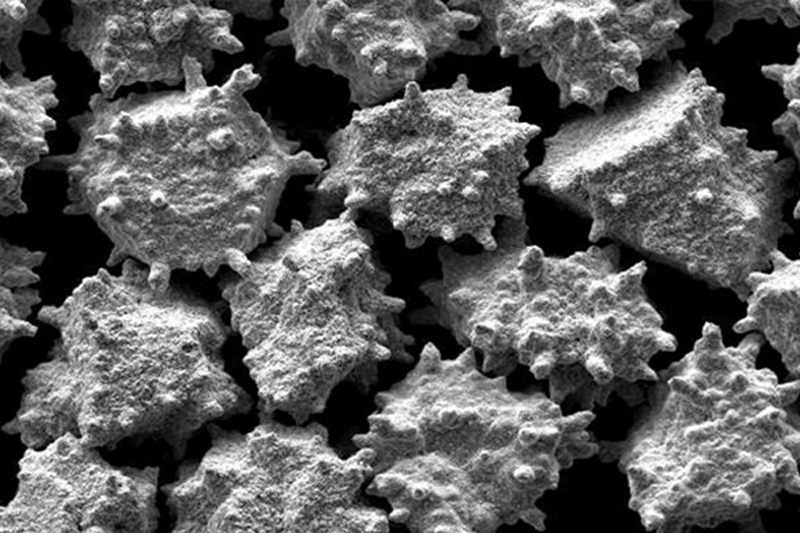

BRM-P2

Medium-high toughness, excellent free cutting ability and more durable than P1, angle crystal shape, produced by using higher MBD diamond as raw materials. For resin bond and Vitrified bond system. Diamond Nickel and Titanium coated is available.

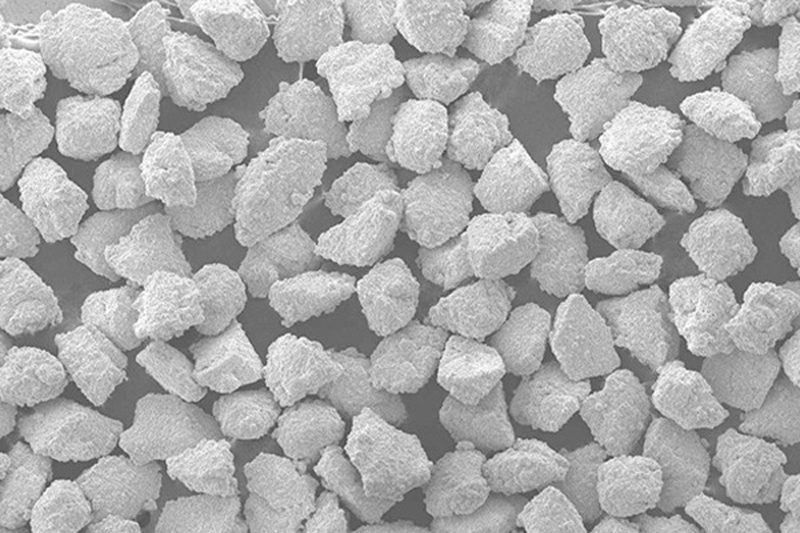

BRM-P3

High toughness, produced by using premium MBD diamond as raw materials. Excellent sharpness and free cutting ability. It offers a long using life and high working efficiency. For resin bond system, vitrified bond system, electroplated tools and etc.

Available Grain Size

50/60 |

60/70 |

70/80 |

80/100 |

100/120 |

120/140 |

140/170 |

170/200 |

200/230 |

230/270 |

270/325 |

325/400 |

|

BRM-P |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

BRM-Z1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

BRM-Z2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

BRM-Z3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

Classifications

BRM-P1, BRM-P2

![[BRM-P] Crushed Mesh Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699c000c8973744.jpg)