0102030405

[BRM-WSD] Micron Diamond Powder for Diamond Wire

Characteristics

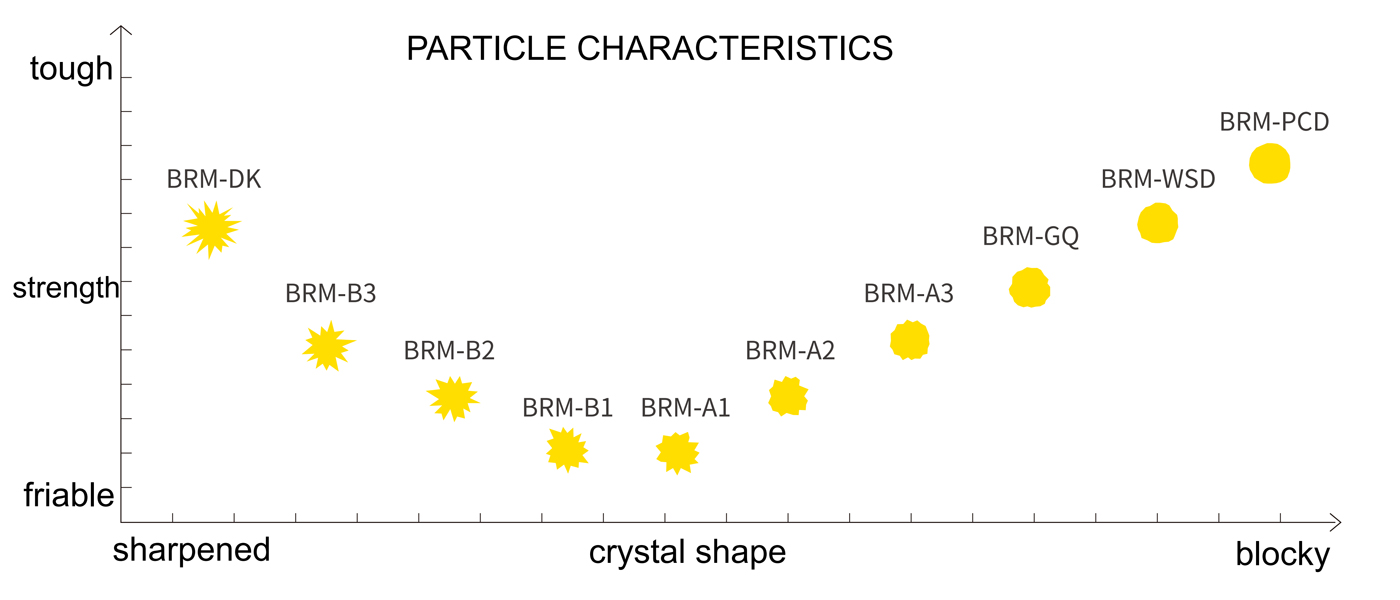

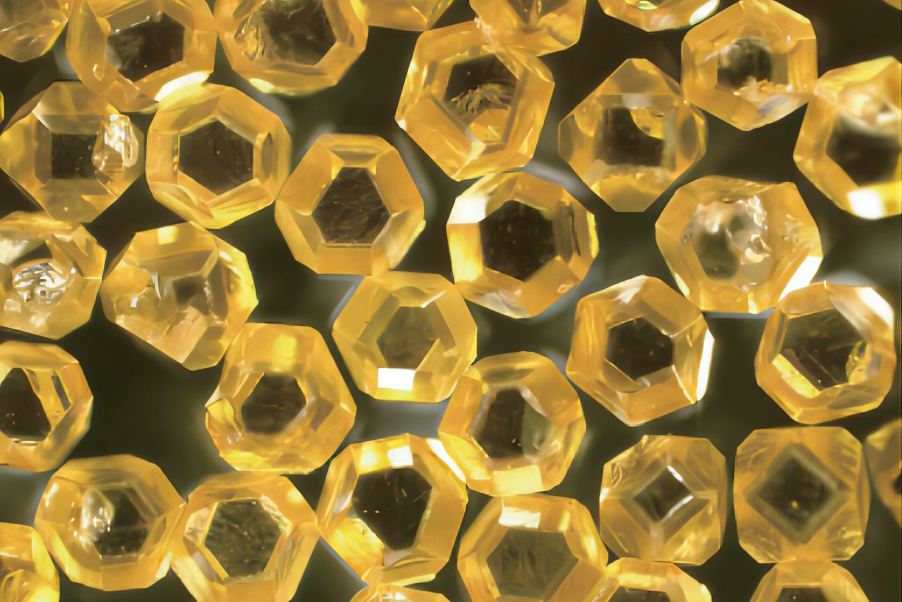

BRM-WSD series are specially designed for diamond wire application.

Standard grade synthetic single crystal micron diamond powder designed for diamond wire. Produced by specialized technique with premium grade.

With high strength, highly concentrated particle size distribution & effective particles, strictly control of rod-like and flaky shape particle, low impurity, high cutting efficiency of good sharpness, prominent dispersity and wear resistance.

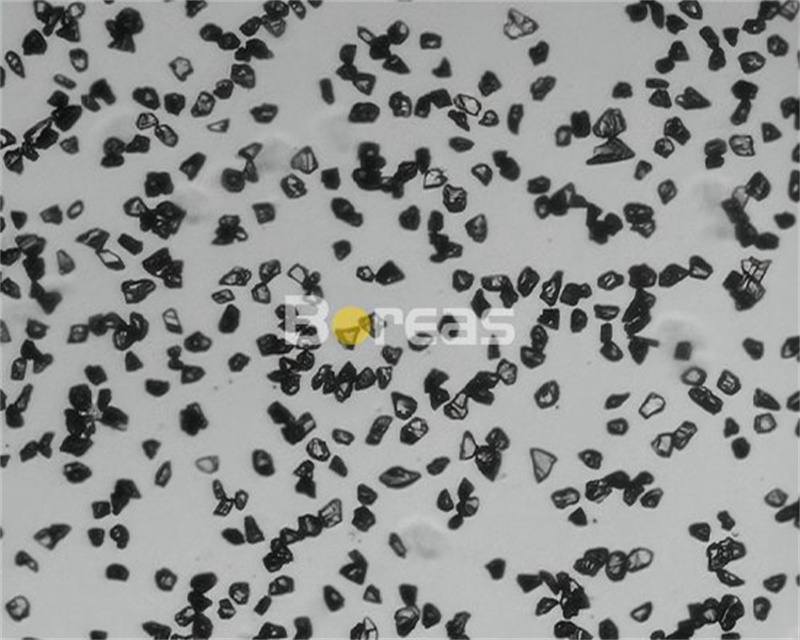

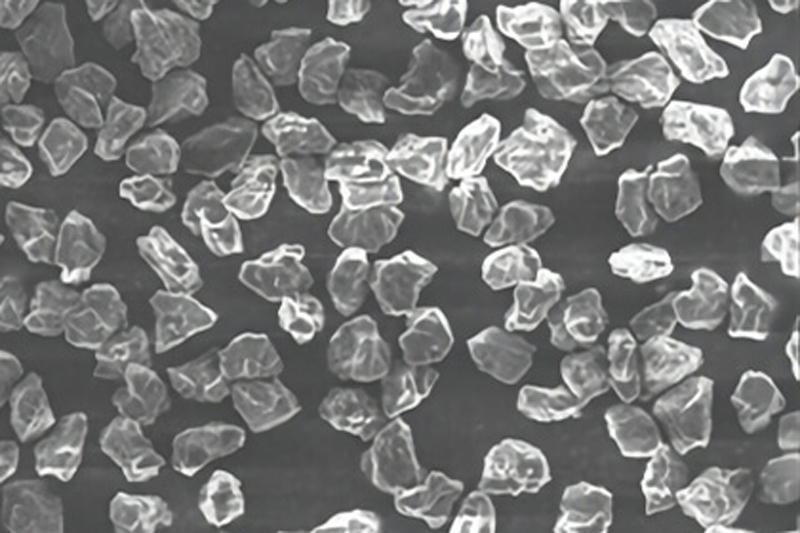

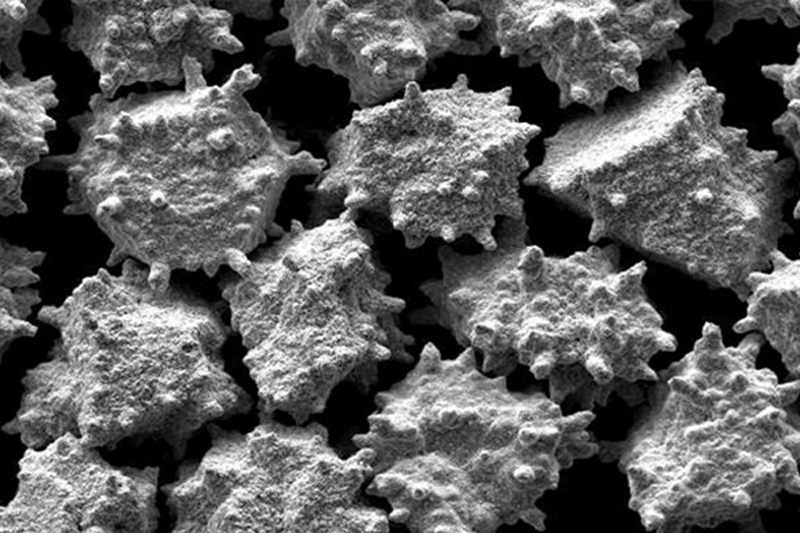

Grit Shape

With high cutting efficiency of good sharpness, irregular shapes exceptional cleanliness, extended lifespan, and superior finishing quality. There are no large particles, which increases the effective

grinding force and the diamond particle content and enhances the wear resistance

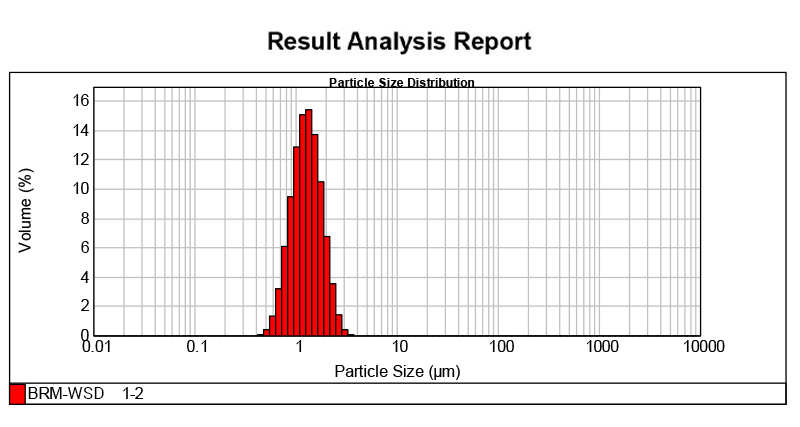

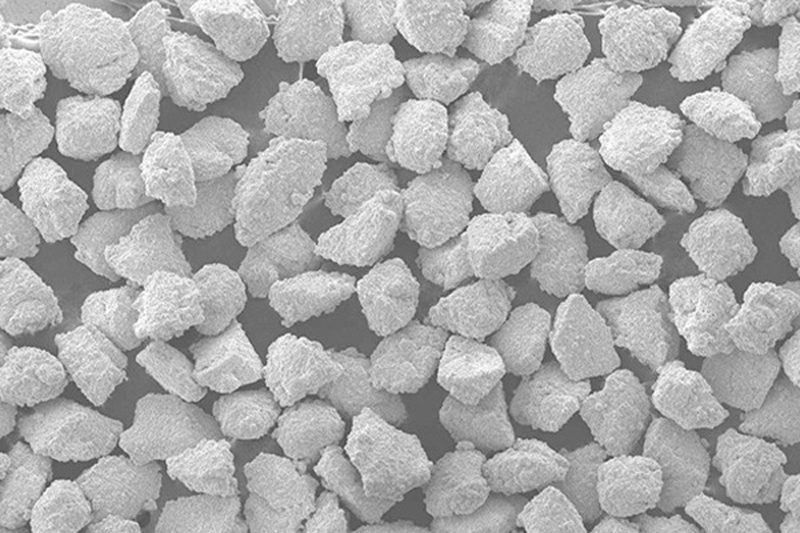

Particle Size Range

Precision grading and tight tolerances ensure high lot-to-lot consistency. Boreas diamond powder consistently delivers exceptional results, thanks to our narrow and precise particle size distribution, which has earned us a strong reputation in the market

Applications

Make diamond wire for dicing & slicing monocrystalline silicon, polycrystalline silicon, sapphire, LCD, magnetic materials, semiconductor materials, also used for other premium diamond grinding & polishing tools.

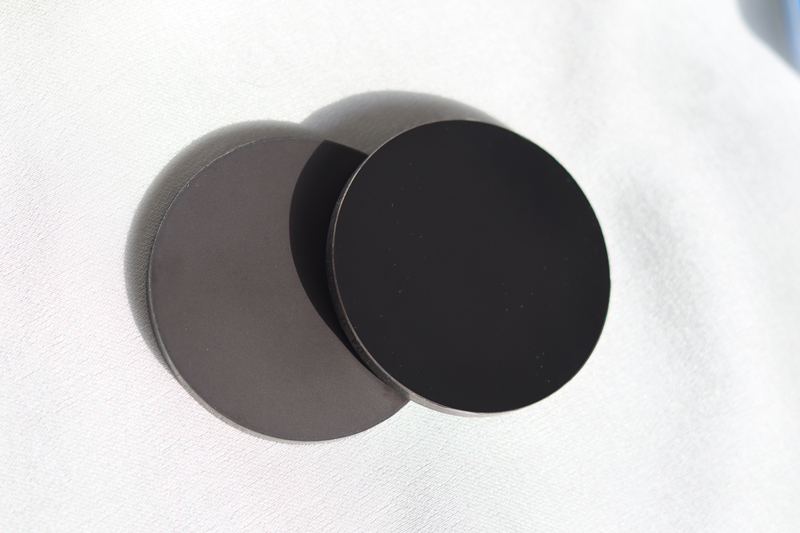

Available Coatings

Chemical Nickel coating, Electroplated Nickel coating, Titanium-Nickel composite coating, customized coatings are also available. Coated metal can improve heat dissipation and reduce heat damage thus protect the diamond (decrease diamond carbonization when sintering at ultrahigh temperature).

(Nickel coating can greatly enhance the retention between diamond particles and core wire.)

Micron Diamond Available Grit Size Chart

Size |

3-6 |

4-6 |

4-8 |

4-9 |

5-10 |

6-12 |

7-14 |

8-12 |

BRM-PCD |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

Size |

8-16 |

10-20 |

12-22 |

15-25 |

20-30 |

22-36 |

20-40 |

30-40 |

BRM-PCD |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

![[BRM-WSD] Micron Diamond Powder for Diamond Wire](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/66026a0d7c9c158191.jpg)