0102030405

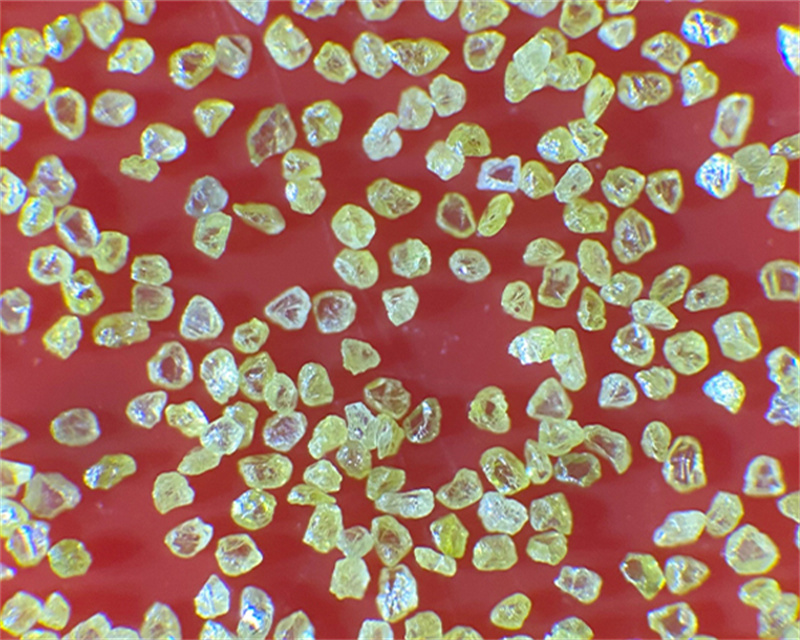

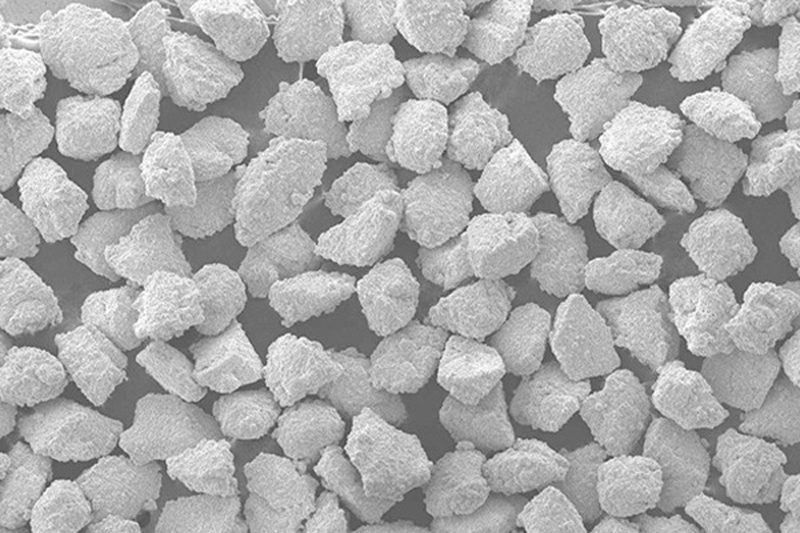

[BRM-Z] Reshaped Mesh Diamond Powder

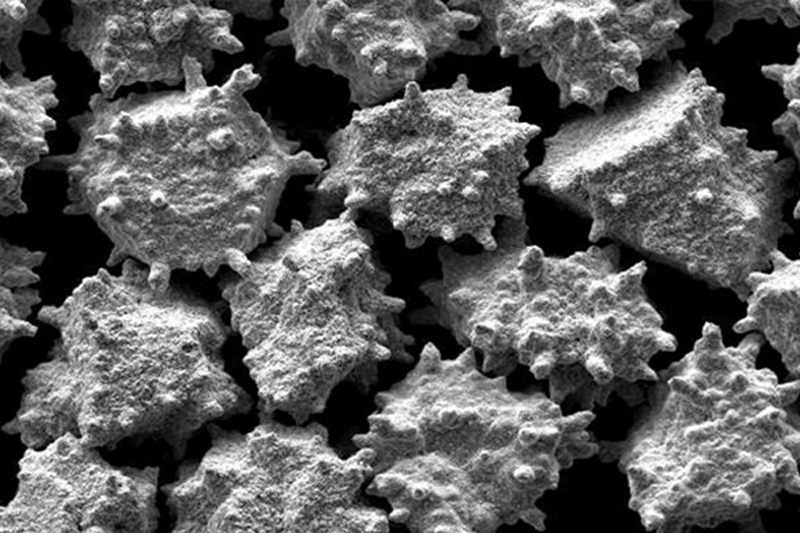

BRM-Z1

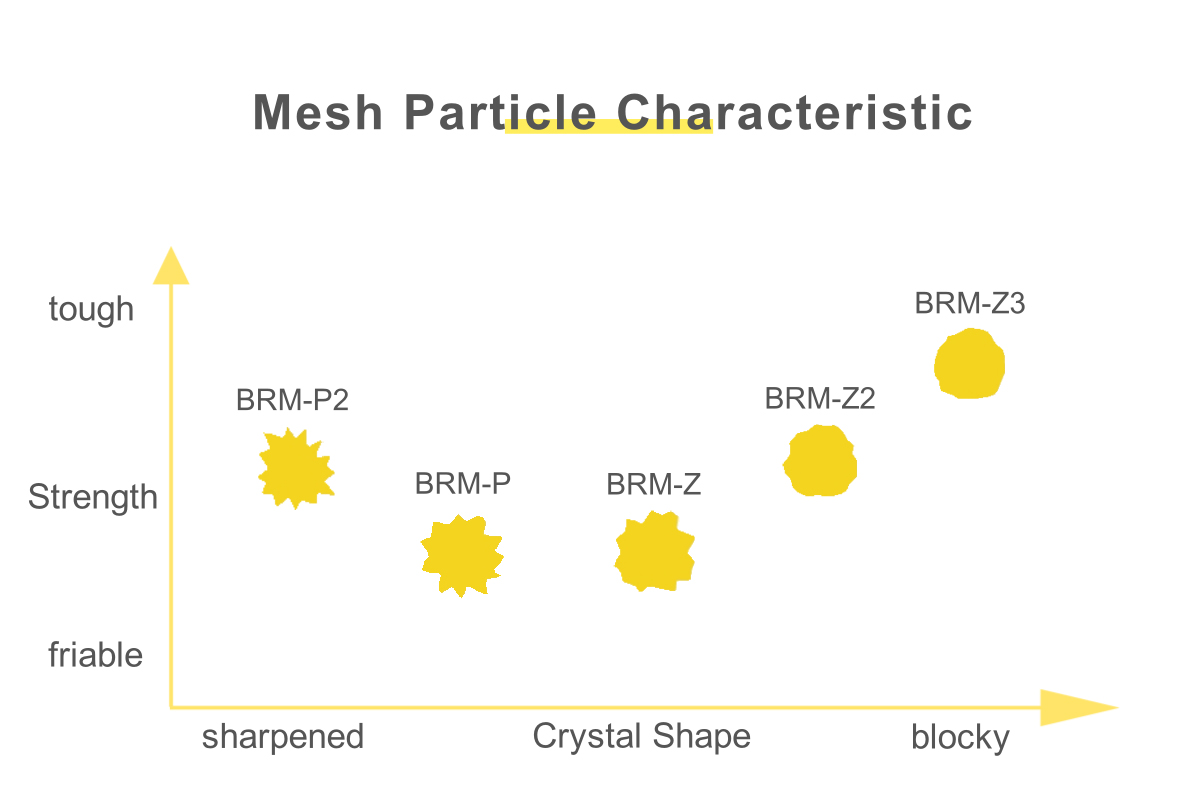

Medium-High toughness, rough and irregular crystal shape, more durable than BRM-P1, applied in ceramic bonded, resin boned and all kinds of electroplating products, for processing stones, hard alloys, magnetic materials, nature diamond, gem, etc.

It is also available in Nickel and Titanium coating.

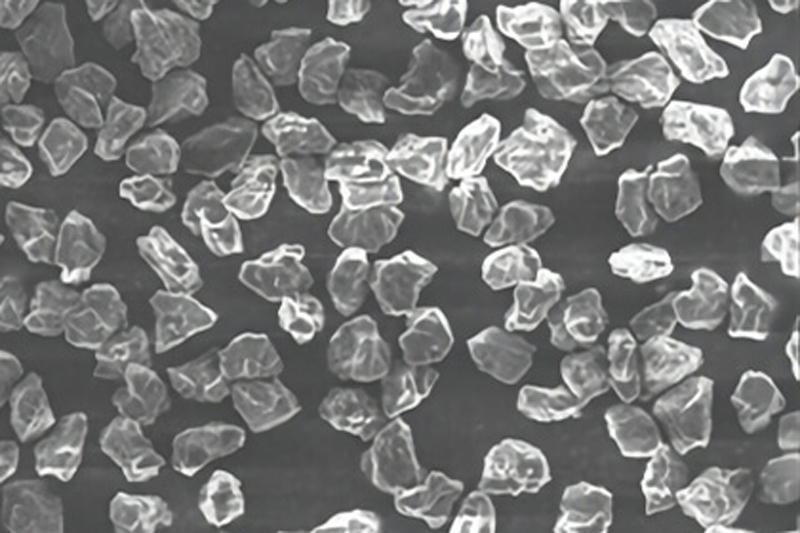

BRM-Z2

High toughness, blocky shapes, produced by using high grade MBD diamond as raw materials, by using specialized crushing/reshaping technique. More durable than Z1, provides the shining surface on the workpiece. It is suitable for resin bond system, vitrified bond system, electroplated tools.

It is also available in Nickel and Titanium coating.

BRM-Z3

premium diamond powder features high toughness and blocky shapes, produced using high-grade MBD diamond as raw materials and a specialized crushing/reshaping technique. Applied in the condition requiring high grinding rate, like electroplated tools to grind and polish stones, ceramics, glasses, and magnetic materials, etc.

It is also available in Nickel and Titanium coating.

Description

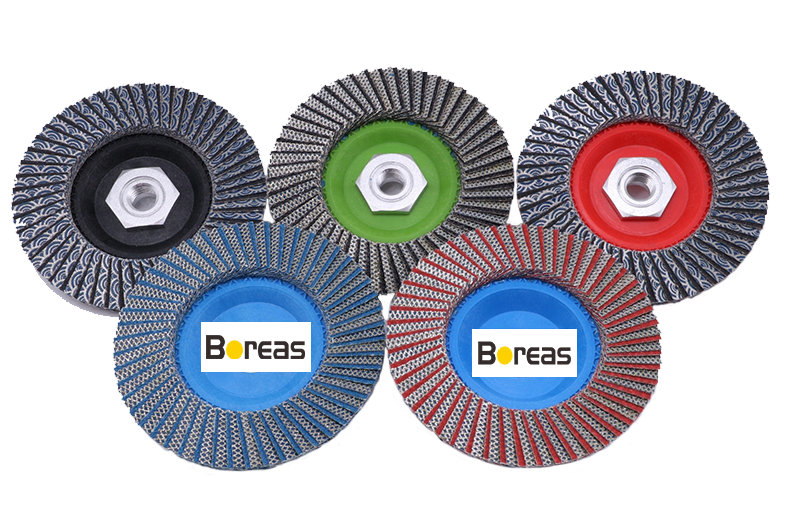

Applications: Making metal bond, vitrified bond, electroplated diamond

tools for processing 3C industry, gem, core drilling of glass, ceramic, tungsten carbide.

Available Size: 50/60 – 325/400

Classifications: BRM-Z1, BRM-Z2, BRM-Z3

Available Grain Size

50/60 |

60/70 |

70/80 |

80/100 |

100/120 |

120/140 |

140/170 |

170/200 |

200/230 |

230/270 |

270/325 |

325/400 |

|

BRM-P |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

BRM-Z1 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

BRM-Z2 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

BRM-Z3 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

Classifications

BRM-Z1, BRM-Z2, BRM-Z3

![[BRM-Z] Reshaped Mesh Diamond Powder](https://ecdn6.globalso.com/upload/p/1176/image_product/2024-03/660699edb1aea10591.jpg)